HARDWARE COATING

- Services

- HARDWARE COATING

Service Details of Hardware PVD Coating

Hardware PVD (Physical Vapor Deposition) coating services gained immense popularity in different industries due to their capacity to improve the durability, appearance, and performance of tal and non-metallic exteriors. PVD coating pertains to the testimony of a thin film of material onto a substrate through a vacuum process. This method delivers several benefits, bringing in a select option for many applications.

Benefits and features of Hardware PVD Coating Services

- Improved Durability: PVD coatings especially improve the wear opposition of hardware elements. The deposit in the delicate film acts as a defensive obstacle, preventing abrasion and extending the slides’ pants-coated portions.

- Improved Corrosion Resistance: Hardware elements revealed to harsh atmospheres can profit from PVD layers. The narrow film structures a corrosion-resistant coating that shields the substrate’s material from moisture, chemicals, and other corrosive dealers.

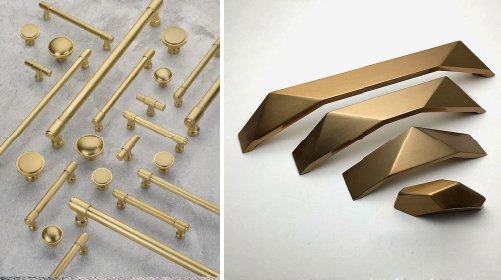

- Improved Aesthetic Appeals: PVD coatings arrive in an assortment of colors and finishes, permitting customizations. This not only adds an aesthetic component to the hardware but also maintains its impression over time, as the layers are highly invulnerable to disappearing and contusion.

- Reduced Friction and Wear: PVD-coated surfaces present lower variance coefficients, making them excellent for shifting portions in machinery. This reduces the risk of wear and tear, eventually enhancing efficiency and longevity.

- Tolerance to High Temperatures: Some PVD coatings can resist high-temperature atmospheres, getting them sensible applications and where components are uncovered to incredibly crucial heat or immediate temperature fluctuations.

Conclusion:

In conclusion, hardware PVD coating services offer a populace of advantages, enhanced by durability, corrosion resistance, aesthetic appeal, and improved interpretation. Whether for ornamental or practical objectives, PVD coatings have evolved a vital role in technology in contemporary manufacturing and are constantly evolving to satisfy the diverse group needs of various enterprises.